When the waterproof coil is used in the building, in fact, there are some technical regulations for the lap length of this coil. The materials used are different, the construction process is different, the building mode is different, and the lap length of the waterproof coil is also different.

?

In China's building, the waterproof coil in the lap length, should follow the relevant provisions of the national standard 50208-2002, for example, in the construction of underground waterproof engineering, the relevant quality acceptance specifications within their own, the short side of the two waterproof coils and the long side of the waterproof coil lap width can not be less than 100 mm long. And in the provisions of the national standard GB50207-2002, the indoor engineering quality acceptance, the use of waterproof coil in the lap construction method, the upper and lower layers and the two pieces of coil close to each other must be opened.

?

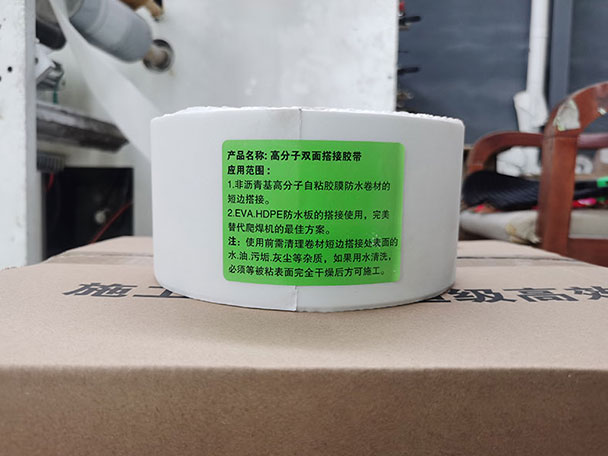

After all, each waterproof coil because of its own material and construction methods, there are also some differences, for example, in the lap width, when using asphalt waterproof coil, empty paving method and point adhesion method, as well as full adhesion method, the lap length is also different, they are between 100 mm and 150 mm. When the polymer waterproof coil is used, it is generally maintained at a length of about 80 to 100 mm according to the different laying methods, and the high synthetic molecular waterproof coil used is about the same length as the polymer modified waterproof coil.

?

However, if you use a single seam welding method, the general length will be maintained at about 60 mm, and the use of effective welding method, according to regulations, the length can not be less than 25 mm. Therefore, when laying waterproof coils, the length of the lap joint is closely related to the material and construction method of the waterproof material.

Current position:

Current position:

Recommended

Recommended

Release time:

2024/8/5 0:00:00

Release time:

2024/8/5 0:00:00

browse:66

browse:66

Business license

Business license